Convertitori di potenza per l'alimentazione di elettrolizzatori

Massimo Bertazza - Secom

Sommario

(in lingua inglese)

- Electrolyzer power supply systems

- Custom development of power converters

- AC/DC power converters

- Inverter, F3E, AFE

- Control board

- Integrated systems

- Power conversion system for Electrolyzer power supply

Electrolyzer power supply systems

Thyristor Technology

- Robustness

- Efficiency

- Low Cost

- Scalable

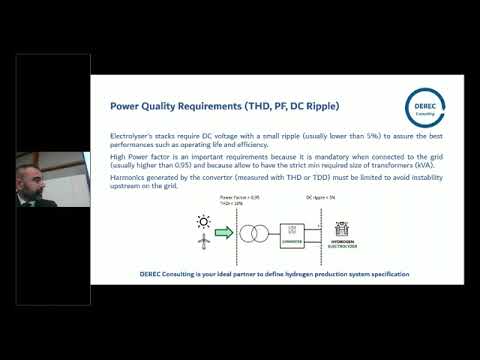

- Low Power Factor (<0.7)

- High THD

- Transformer and cables oversizing

- High ripple

- Network instability

- One way

- Difficult modularity

IGBT Technology

- High Power Factor (>0.98 with AFE)

- Low THD (<5% with AFE)

- Low ripple

- Network stability

- Bidirectional (AFE)

- Easy modularity

- DC/DC converter after AFE needed if the Vdc of the electrolyzer starts at lower voltage than the AFE Vdc.

- Cost

- Efficiency

Custom development of power converters

- Specification: customer input data, electrolyzer characteristics, power quality constraints...

- Conceptual design: identification of one or more solutions compared. Simulation

- Detailed design: electrical design, choice of components, mechanical design

- Prorpotyiping and Testing: construction, type tests, checks, inspections

- Production Design: design optimization, quality controls, certification

- Production: programming and series production

SECOM has developed expertise and gained experience in the power converter market for various industrial applications Drives and auxiliary device designed in collaboration with our customers are further examples of the added value that the company can offer to innovative applications inverter family provides a different and new answer for all AC applications Driving AC motor, renewable power sources, regenerative converter as Front End power supply SECOM has started selling LV drives since 2007.

The choice between liquid cooling and air cooling depends on the specific application requirements and company preferences.

SECOM has in-depth expertise in both technologies and can provide customized solutions based on the needs.

Main Points

- Thermal Efficiency

High thermal efficiency with precise temperature control.

- Heat Management

The ability to dissipate heavy workloads and large amounts of heat

- SIlent

Quiet operation, ideal for noise sensitive application

- Reduced Dimensions

Higer power density

- Complexity

Attached, you can download the full pdf of the presentation.

Thyristor Technology

- Robustness

- Efficiency

- Low Cost

- Scalable

- Low Power Factor (<0.7)

- High THD

- Transformer and cables oversizing

- High ripple

- Network instability

- One way

- Difficult modularity

IGBT Technology

- High Power Factor (>0.98 with AFE)

- Low THD (<5% with AFE)

- Low ripple

- Network stability

- Bidirectional (AFE)

- Easy modularity

- DC/DC converter after AFE needed if the Vdc of the electrolyzer starts at lower voltage than the AFE Vdc.

- Cost

- Efficiency

Custom development of power converters

- Specification: customer input data, electrolyzer characteristics, power quality constraints...

- Conceptual design: identification of one or more solutions compared. Simulation

- Detailed design: electrical design, choice of components, mechanical design

- Prorpotyiping and Testing: construction, type tests, checks, inspections

- Production Design: design optimization, quality controls, certification

- Production: programming and series production

SECOM has developed expertise and gained experience in the power converter market for various industrial applications Drives and auxiliary device designed in collaboration with our customers are further examples of the added value that the company can offer to innovative applications inverter family provides a different and new answer for all AC applications Driving AC motor, renewable power sources, regenerative converter as Front End power supply SECOM has started selling LV drives since 2007.

The choice between liquid cooling and air cooling depends on the specific application requirements and company preferences.

SECOM has in-depth expertise in both technologies and can provide customized solutions based on the needs.

Main Points

- Thermal Efficiency

High thermal efficiency with precise temperature control.

- Heat Management

The ability to dissipate heavy workloads and large amounts of heat

- SIlent

Quiet operation, ideal for noise sensitive application

- Reduced Dimensions

Higer power density

- Complexity

Attached, you can download the full pdf of the presentation.

Video

Fonte: Fiera Idrogeno ottobre 2023 Idrogeno oggi e domani: esperienze concrete e casi applicativi

Mercati: Chimica, Petrolchimica, Plastica

Parole chiave: Elettrolizzatori, Idrogeno

- Air Liquide Italia Service

- Clean Hydrogen Partnership

- RSE - Ricerca sul Sistema Energetico

- Ansaldo Energia

- Precision Fluid Controls

English

English