Produzione di idrogeno verde, elettrolizzatori industriali in Italia

La via italiana nella produzione di idrogeno verde, elettrolizzatori industriali made in Italy

Saro Capozzoli - H2 Energy

Sommario

(PDF in lingua inglese)

- Introduction on technologies

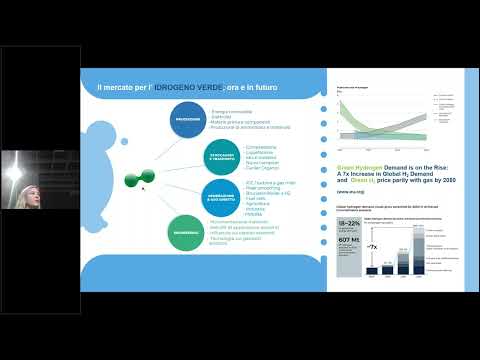

- Increase of hydrogen demand from the market

- Hydrogen is a key driver for energy mix

- Main technologies comparison

- AEM System

Introduction on technologies

Actually the most used low temperature technologies based on water electrolysis are the following:

- Traditional alkaline with liquid electrolyte (AEL); the most used and widespread for industrial applications

- Polymer or Proton, Electrolyte Membrane (PEM); initially relegated to Chemical Lab; Now it is beginning to be used even in energetic and industrial applications

- Alkaline with Electrolyte Membrane (AEM); the most innovative and promising technology in terms of cost reduction and performance increase.

Increase of hydrogen demand from the market

- "Green" hydrogen (from electrolysis+RES)

- Not only for industrial applications (residential, automotive, etc)

- Reduction of dimensions (electrolyser, storage and FC)

- In high pressure (differential pressure transfer, compact storage)

AEM System

The acronym of "Alkaline Electrolyte Membrane" PFD AEM or "Alkaline Exchange Membrane"; it is a optimization between PEM and traditional alkaline, taking the advantages of both technologies and it is attracting more and more attention from electrolysers manufacturers due to the simplicity of its hardware.

H2 ENERGY is developing new AEM 200 and 500-kW single stack proprietary units to be launched in Q1- Q2 in 2023 Our goal is to design a modular skid for a plug and play solution in shipping containers for outdoor instalments or enclosed cabinets for indoor applications.

Attached, you can find the complete pdf of the presentation.

Actually the most used low temperature technologies based on water electrolysis are the following:

- Traditional alkaline with liquid electrolyte (AEL); the most used and widespread for industrial applications

- Polymer or Proton, Electrolyte Membrane (PEM); initially relegated to Chemical Lab; Now it is beginning to be used even in energetic and industrial applications

- Alkaline with Electrolyte Membrane (AEM); the most innovative and promising technology in terms of cost reduction and performance increase.

Increase of hydrogen demand from the market

- "Green" hydrogen (from electrolysis+RES)

- Not only for industrial applications (residential, automotive, etc)

- Reduction of dimensions (electrolyser, storage and FC)

- In high pressure (differential pressure transfer, compact storage)

AEM System

The acronym of "Alkaline Electrolyte Membrane" PFD AEM or "Alkaline Exchange Membrane"; it is a optimization between PEM and traditional alkaline, taking the advantages of both technologies and it is attracting more and more attention from electrolysers manufacturers due to the simplicity of its hardware.

H2 ENERGY is developing new AEM 200 and 500-kW single stack proprietary units to be launched in Q1- Q2 in 2023 Our goal is to design a modular skid for a plug and play solution in shipping containers for outdoor instalments or enclosed cabinets for indoor applications.

Attached, you can find the complete pdf of the presentation.

Video

Fonte: mcT Oil & Gas novembre 2022 Dall’Oil&Gas all’idrogeno. PNRR, transizione energetica, raffinerie e produzione di idrogeno

Mercati: Chimica, Petrolchimica, Plastica

- mcT ATEX Antincendio

- MASE - Ministero dell'Ambiente e della Sicurezza Energetica

English

English